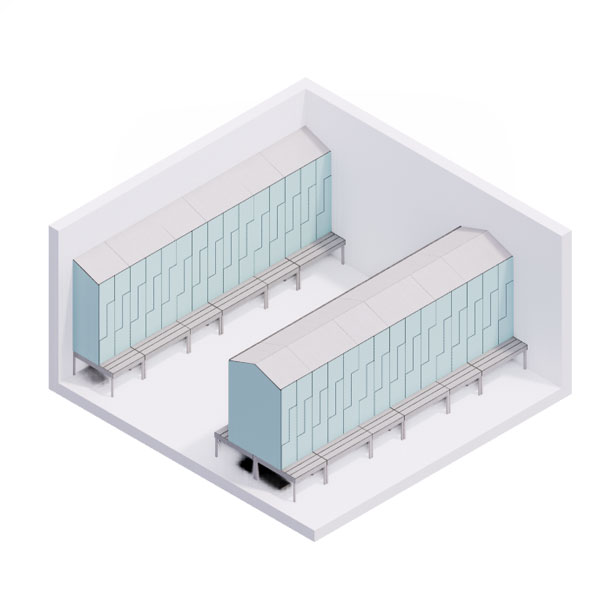

HPL lockers: durability and moisture resistance in public spaces

A changing room that smells fresh, looks tidy and works hard every day is no accident. You need materials that resist splashes, steam and knocks from bags and trolleys. HPL lockers do exactly that and still look great years later. If you plan a gym, pool, school or workplace, you can set a higher bar for hygiene and uptime. Read on and use these tips to make confident choices.

In this article you will learn…

- why HPL handles water, steam and everyday wear so well;

- how HPL compares with metal and MFC in cost and lifespan;

- where HPL lockers shine in public projects and why;

- which locks, hinges and bases work best in wet zones;

- how to install for stability and fast cleaning;

- how to clean HPL surfaces without damaging them.

What makes HPL lockers stand up to moisture?

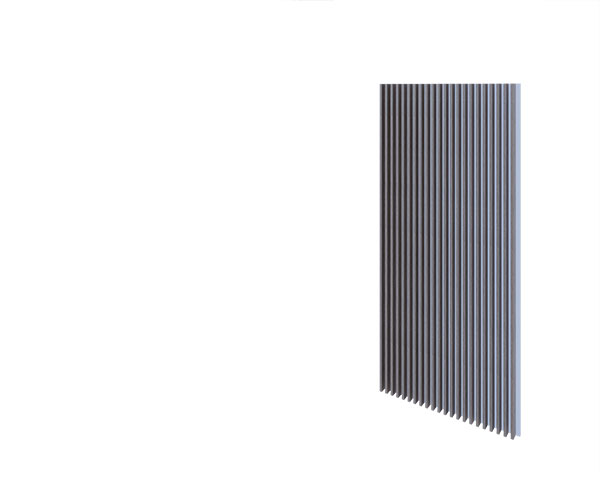

HPL, or high-pressure laminate, used here as compact (solid grade) HPL, is a dense, solid-core panel pressed under heat and high pressure from resin‑impregnated papers. This structure is highly water‑resistant and does not require edge banding, removing common weak points where moisture can enter. Properly fabricated and installed compact HPL does not swell from routine splashes or humidity, even in poolside zones. The result is stable doors and sides that keep their shape.

Here is a quick snapshot of properties that matter in public spaces. Treat it as a checklist when you compare materials with similar looks but different cores. Use it to assess if a locker will cope with the real world, not only with a brochure photo:

- high resistance to water and steam;

- high impact resistance against knocks and slams;

- non-porous, hygienic surface for easy cleaning;

- colourfast surface that tolerates common cleaning agents;

- edges that do not need banding, so no weak points.

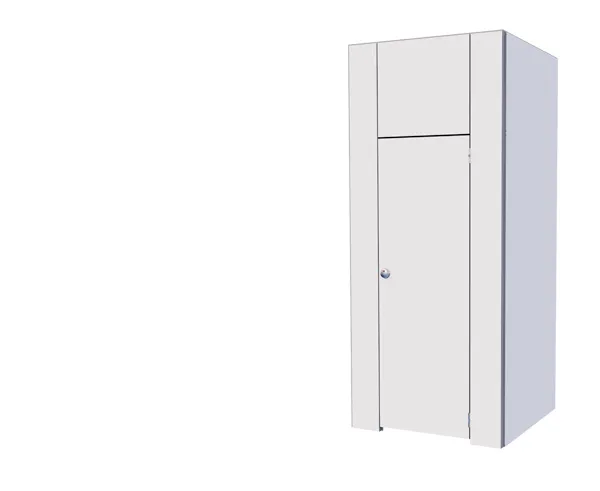

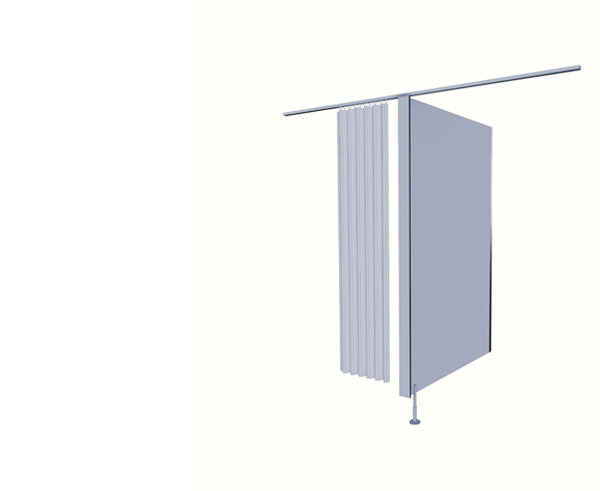

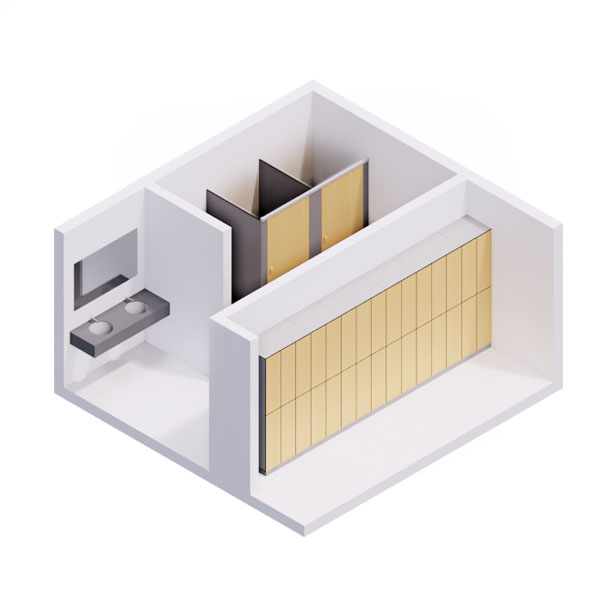

You also gain design freedom. You can choose full-height doors or Z-locker shapes to fit long coats and backpacks. Perforations or discreet gaps add airflow without inviting dust. In wet rooms, compact HPL works well on aluminium or stainless plinths or legs to keep bases off the floor.

How do HPL lockers compare with metal or MFC?

Powder-coated steel can dent and may corrode in chlorinated or coastal air, especially if coatings are damaged. MFC or MDF with edge banding often swells where water finds a seam, which leads to broken doors and stuck locks. Compact HPL resists both issues and typically delivers longer service life in wet and high-traffic areas, which can reduce replacements and downtime. You also get a stable look because doors stay flat and hinges keep alignment.

Where do HPL lockers perform best in public spaces?

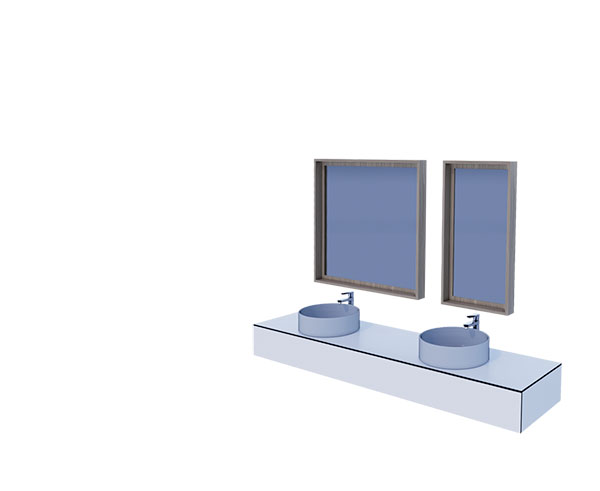

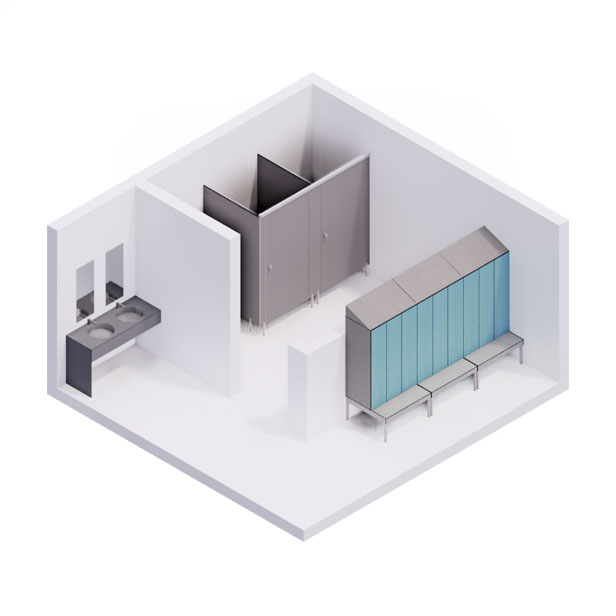

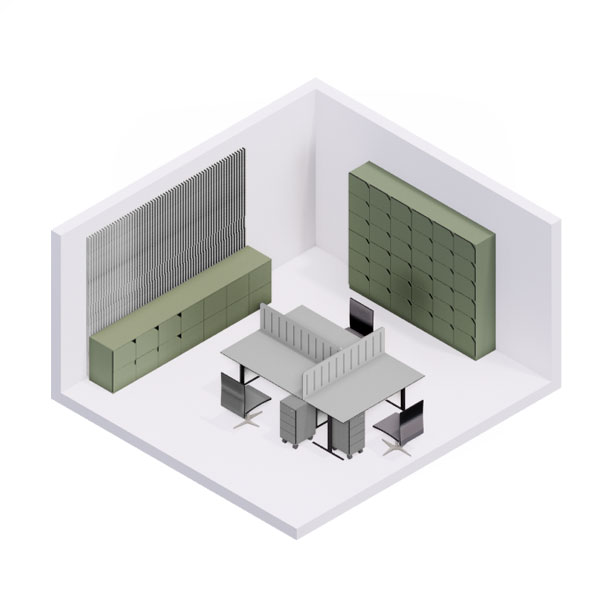

You see the biggest wins in gyms, pools and spa areas with frequent clean-downs. Schools and universities benefit from impact resistance in corridors and changing rooms. Healthcare and lab spaces value the non-porous surface and fast wipe-down routines. Office end-of-trip facilities gain durable storage without the maintenance headaches.

Transit hubs and stadiums need robust lockers that face crowds, wet coats and rapid turnarounds. HPL handles that traffic and cleans quickly between events. In staff areas for logistics and manufacturing, the compact core resists knocks from tools and trolleys.

If you plan lockers for mixed-use buildings, HPL helps you unify the look across wet and dry zones. You can use one material with different bases and locks to match each area. That simplifies spare parts and training for your team. It also keeps the user experience consistent across floors and rooms.

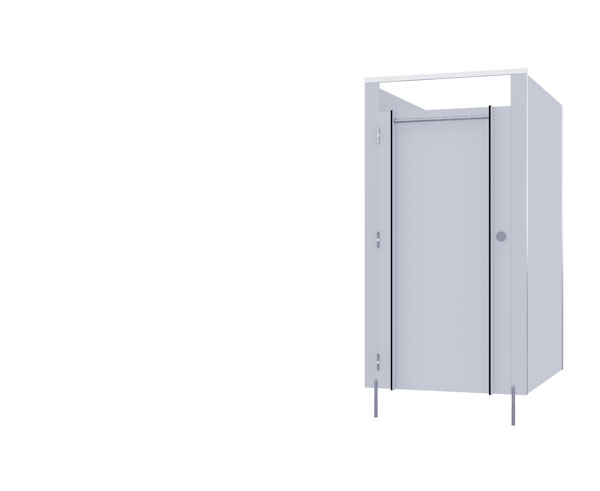

How do you plan layouts for high-traffic changing rooms?

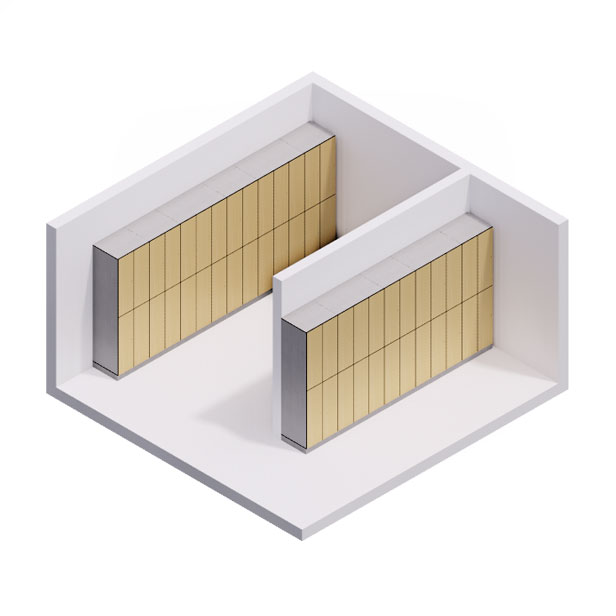

Start with flow: entrance, bench, locker reach and exit should feel natural and safe. Keep clear aisles for bags and wheelchairs, and allow doors to open without clashing. Mix sizes: full-height for coats, half-height for everyday items and Z-lockers where space is tight. Add ventilation gaps and drain-friendly bases in wet areas to make cleaning faster.

Which locks and fittings should you choose?

Pick hardware for the environment first, then for the user journey. In wet or chlorinated zones, choose stainless steel (AISI 304 or 316) hinges, screws and handles. For locks, decide how people access: coin-return, padlock hasp, mechanical code or RFID. If you run a membership system, RFID locks reduce key management and cut lost-time issues.

Continuous (piano) hinges add strength to tall doors. Door bumpers, door limiters and robust coat hooks extend life. In heavy-use sites, metal number plates and captive coin locks handle daily cycles better than plastic.

How do you meet accessibility needs?

Plan lower compartments and easy-grip handles within reach ranges. Use contrasting colours for doors, frames and numbers to aid low-vision users. Set code locks or RFID readers at heights that work for seated and standing users. Keep clear floor space in front of accessible lockers, and avoid door swings that block transfer or turning zones.

How do you install HPL lockers for long-term performance?

A stable base is the start of a stable installation. Level every run with adjustable feet or a continuous plinth, then fix carcasses square and plumb. Use wall anchors where the wall allows, and connect lockers to each other for a rigid block. Leave small expansion gaps at walls and between runs, then cover them with profiles or silicone where needed.

Below you will find simple steps that reduce callbacks and protect your schedule. Share them with your installer and include them in your method statement:

- check floor levels and falls before delivery;

- store panels flat, dry and off the floor;

- use stainless fixings in wet or corrosive zones;

- seal floor junctions and plinths to speed up cleaning;

- align doors, then set hinges and locks after leveling;

- test every lock and hand over spare keys and codes.

When bases are off the floor, cleaning teams can mop without hitting panels. Aluminium or stainless skirting protects the lower edges from trolleys. If you combine lockers with benches, fix bench frames first and coordinate heights. A careful handover with a small box of spares keeps you ready for quick repairs.

How do you clean and maintain HPL lockers?

Daily, use a soft cloth or microfibre with warm water and a mild detergent. Rinse and dry to avoid streaks, especially on dark colours. For limescale, use a gentle descaler, apply briefly and rinse well. Avoid abrasive pads, strong solvents or scouring powders that can dull the surface.

Plan quarterly checks of hinges, screws and locks. Tighten any loose fixings and replace worn bumpers. Lubricate lock cylinders with a suitable product if the manufacturer recommends it. Keep a record of codes and master keys in a secure place.

Which cleaning agents are safe for HPL surfaces?

Neutral pH cleaners are the safest daily choice for HPL. Alcohol wipes are suitable for quick disinfection if you rinse or follow with a damp cloth. Avoid strong chlorinated bleach and never soak doors or hinges. For marker or sticky residue, try a citrus-based cleaner on a cloth and test in an inconspicuous spot. Always rinse and dry to keep the surface looking new.

Ready to specify HPL lockers with confidence?

Focus on the environment, the user flow and the maintenance plan, then choose fittings that match. HPL gives you a tough, water‑resistant core, so the rest comes down to smart details. With good layout, stainless hardware and cleanable bases, lockers stay in service longer. Your team gets fewer headaches and your users get storage that simply works.

Frequently asked questions about hpl lockers

Below you will find short answers you can apply right away. Use them to brief your team or to review a spec before you place an order. If your site has unusual conditions, test a sample panel on location.