Ergonomics and design: how to plan a locker room with lockers?

A locker room is the calling card of your facility and a key element of everyday comfort for users. You want it to work smoothly and look good. Combine ergonomics with aesthetics to create a space that feels intuitive. I’ll walk you through the process step by step. Stay with me and plan your locker room without the stress.

Here are the key points:

- how to arrange lockers and traffic routes without bottlenecks;

- which materials to choose for lockers in humid areas;

- how to plan ventilation, lighting, and color schemes;

- how to maintain hygiene and speed up cleaning;

- which locks and accessories will work best in your locker room;

- how to avoid common mistakes and make smart decisions from the start.

Where To Start When Planning a Locker Room With Lockers?

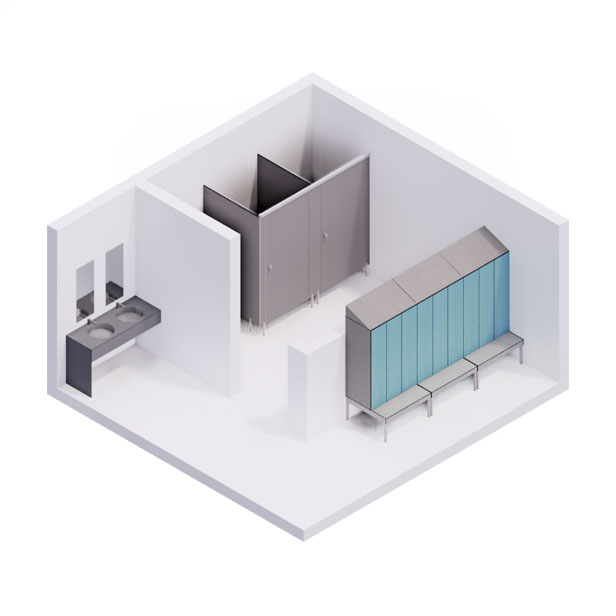

Begin by identifying the number of users and peak hours. Decide whether you need separate zones for women, men, and families. Determine how much space you have for lockers and benches. Check where wet and dry zones will be located.

Next, define the main functional requirements. Write down expectations related to safety, durability, and service. Create a short checklist:

- minimum corridor widths and turning radiuses for service carts;

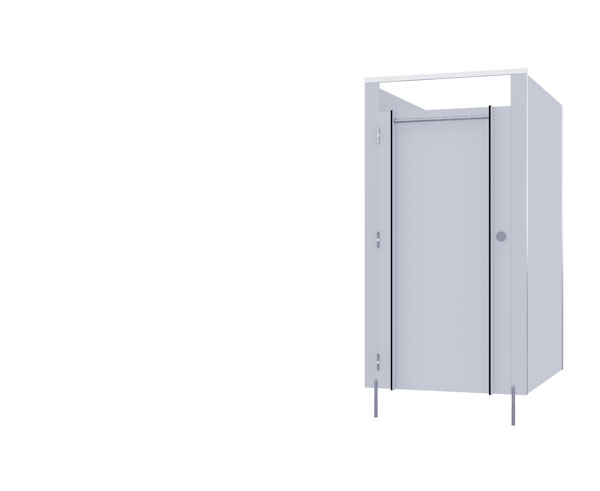

- clear zoning: entrance, deposit area, changing area, showers, exit;

- logical user flow: “entrance → locker → bench → exit”;

- number of lockers matched to real occupancy;

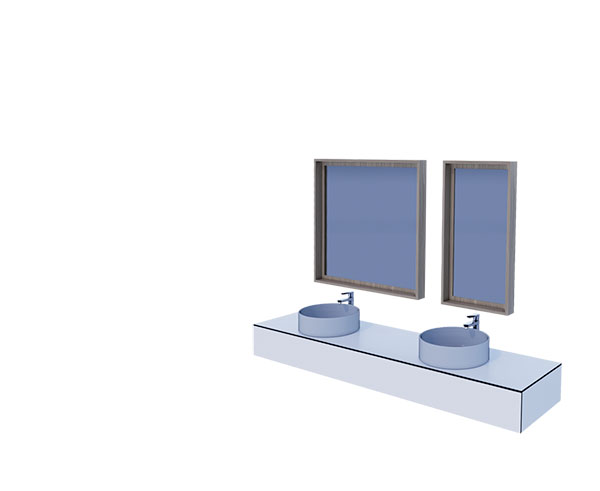

- designated spaces for bins, dryers, and mirrors;

- power outlets and chargers in high-traffic zones.

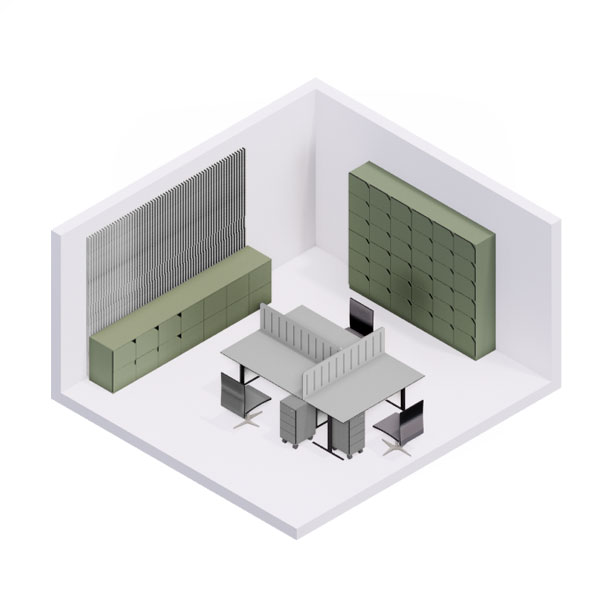

Once you have this data, the first layout draft comes quickly. Start with 2D plans, then check 3D views. Test user flow scenarios. This helps you choose the right locker modules and accessories.

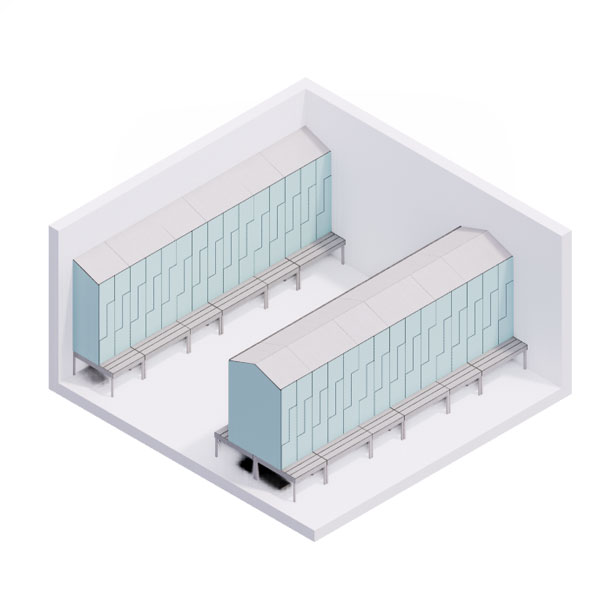

How To Arrange the Layout and Circulation Routes?

Your locker layout should guide users intuitively. Use long corridors for movement and place stop-and-stay areas by benches and mirrors. Avoid dead ends and blind corners. Keep in mind door swing radiuses and ergonomics.

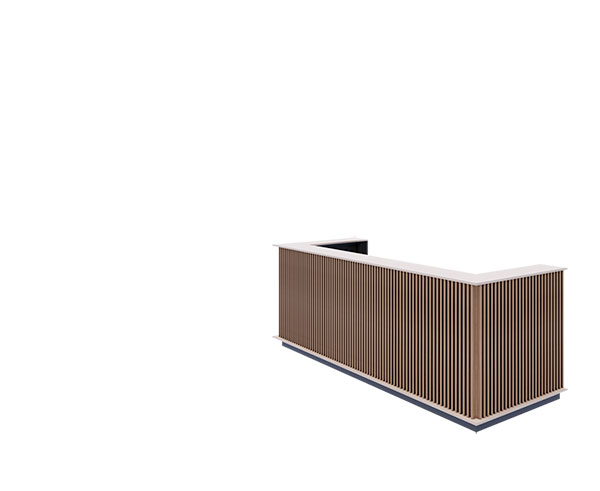

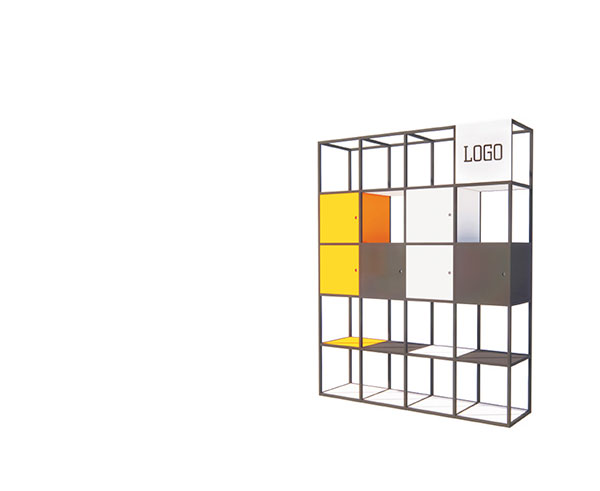

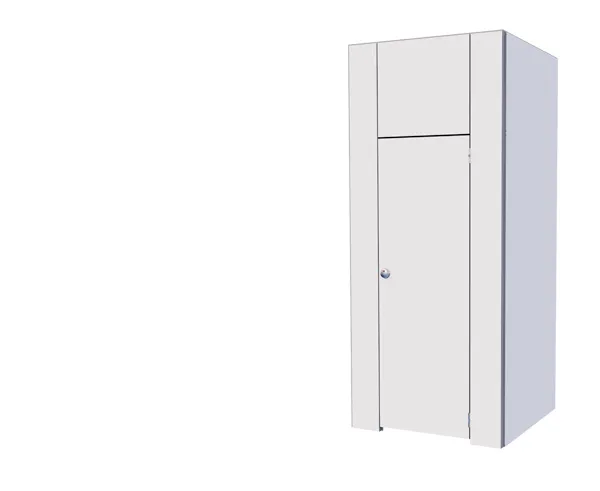

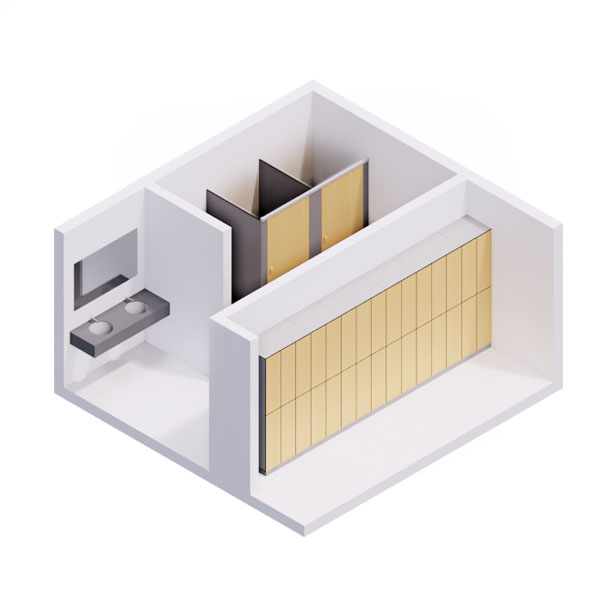

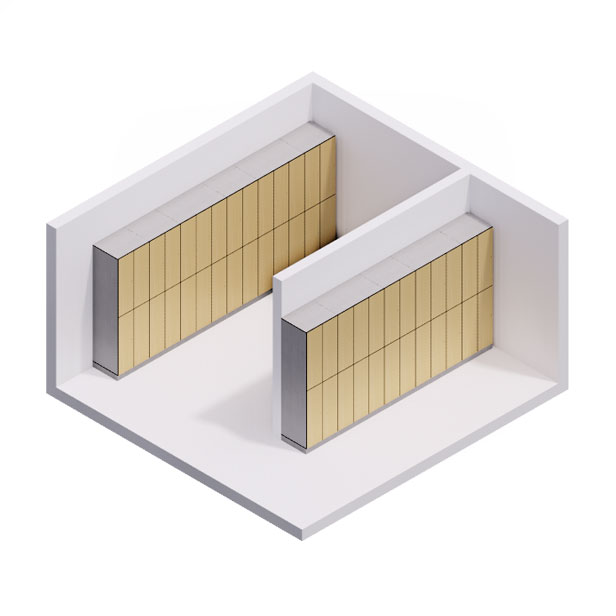

Choose one of three simple schemes: parallel, island, or U-shaped. The parallel scheme works well in narrow rooms, while island layouts fit wider spaces with heavy traffic. In more complex layouts, modular solutions like overhead lockers and corner units (offered, for example, by ALSANIT) can help. Separating entrance and exit also supports a smooth one-direction flow. Finally, test your layout using a simulation or a taped floor mock-up.

How To Choose Locker Materials and Finishes?

In wet zones, choose HPL and stainless steel. Compact HPL resists moisture, impact, and cleaning agents. It keeps its shape, does not swell, and is easy to clean. For inspiration, review product solutions presented by ALSANIT and compare finish options.

In dry zones, you can add laminated boards and wood-effect accents. Quality hardware and hinges matter. Look for soft-close systems and easily replaceable parts.

Pay attention to ventilation. Door perforations and base gaps help release moisture. Pick matte finishes if you want fewer fingerprints. Smooth fronts make cleaning faster and look modern. Ideally, your color scheme should align with your facility’s visual identity.

How To Ensure Hygiene and Easy Cleaning?

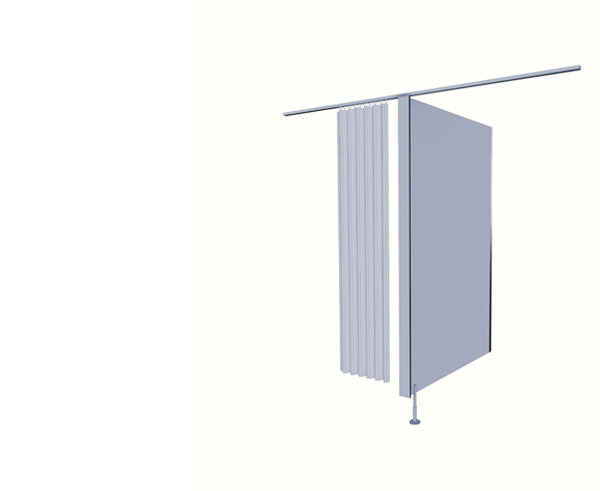

Start by dividing the room into clean and wet zones. Use HPL boards and steel elements in high-risk areas. Protect walls behind benches with panels up to backrest height. Avoid thresholds and narrow gaps where dirt accumulates. Choose rounded bases and suspended furniture. Ensure full access for the cleaning crew.

Did you know? High clearance under cabins and lockers shortens floor cleaning time. In locker room solutions such as sanitary systems and modular furniture, ALSANIT shows how suspended constructions simplify everyday hygiene. Consider using corner bumpers to protect walls and locker fronts.

Choose cleaning products suitable for each material. Plan lockable storage for chemicals and equipment. Establish service procedures and maintenance schedules. Clear rules help maintain the standard for years.

Should You Choose Electronic or Mechanical Locks?

Mechanical locks are simple, inexpensive to maintain, and reliable. They work well where rotation is low and staff manage keys. Electronic locks offer flexibility, coding, and integration with reception. They are useful with high rotation and multiple access zones. Choose based on usage and service budget.

How To Design the Bench and Changing Area?

Place benches close to lockers but not in the main traffic axis. Provide space for storing belongings and comfortable seating. Add hooks near mirrors and at shower entrances. In family changing rooms, use longer benches and modules with changing tables.

Below is a short checklist for a comfortable changing zone. Review it and tick what you already have:

- benches with 420–460 mm seat height and stable structure;

- shelves or shoe baskets under the seat;

- backrests and hooks within arm’s reach;

- full-height mirrors at the exit of the zone;

- modules for families and people with disabilities.

Use non-slip surfaces. In wet zones, add mats and fast-drying floors. Place dispensers and paper towels logically. No one likes searching for basic items.

How Do Lighting and Colors Affect Ergonomics?

Good lighting creates a sense of safety and order. Combine overhead lighting with task lighting by mirrors. Avoid harsh contrasts that strain the eyes. Dim relaxation zones and brighten entrances and exits.

Use color to guide user flow and highlight functions. Pair neutral bases with vibrant accents on locker numbers and pictograms. Matte finishes reduce glare and fingerprints. Small choices like these build overall comfort.

How To Avoid the Most Common Design Mistakes?

The most common mistake is underestimating traffic during peak hours. Another is too little space for benches and changing. Third, using materials that don’t withstand moisture. Fourth, having no maintenance plan. Fifth, skipping layout testing before ordering equipment.

What’s Next for Your Locker Room Project?

Gather user data and sketch a simple plan. Test the layout using a mock-up and verify the requirements checklist. Only then choose locker modules, benches, and accessories. This approach helps you build a locker room that works from day one.

Frequently Asked Questions About Designing a Locker Room With Lockers

Below are short answers to questions that often come up during planning. They offer practical guidance to help you make quick decisions. Apply them directly to your project.