HPL vs. particle board – which material is better for lightweight construction?

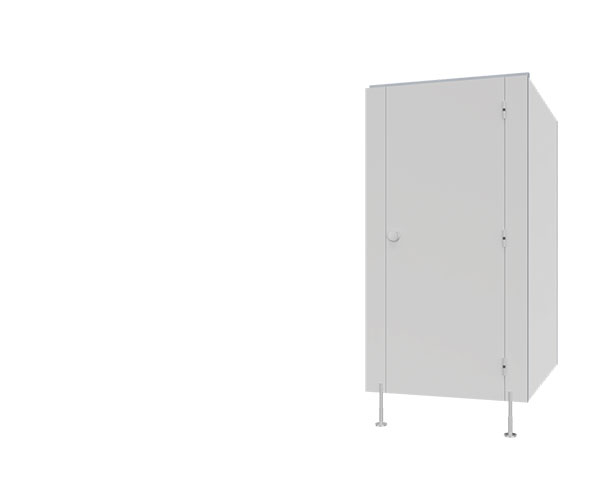

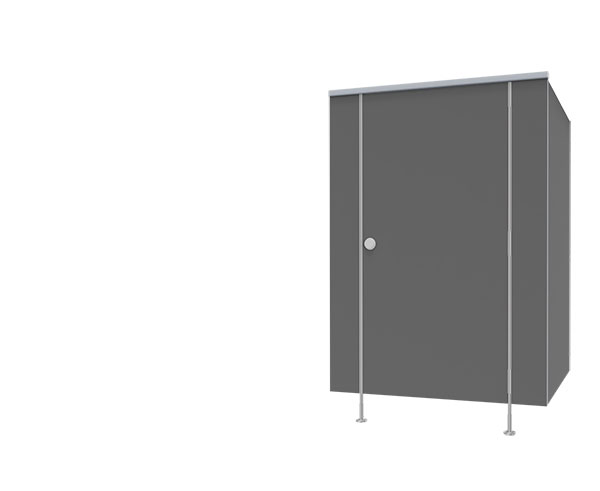

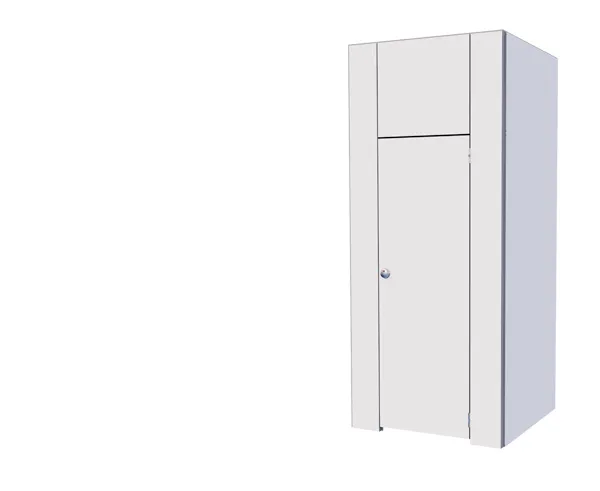

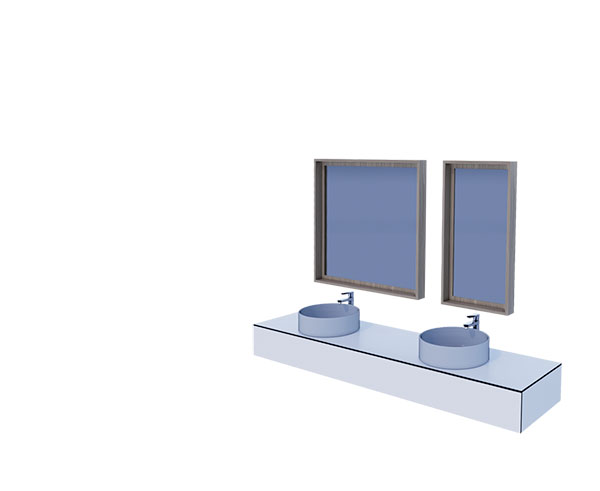

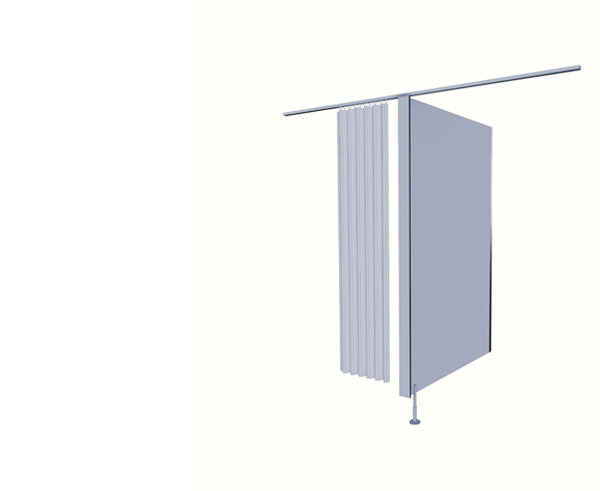

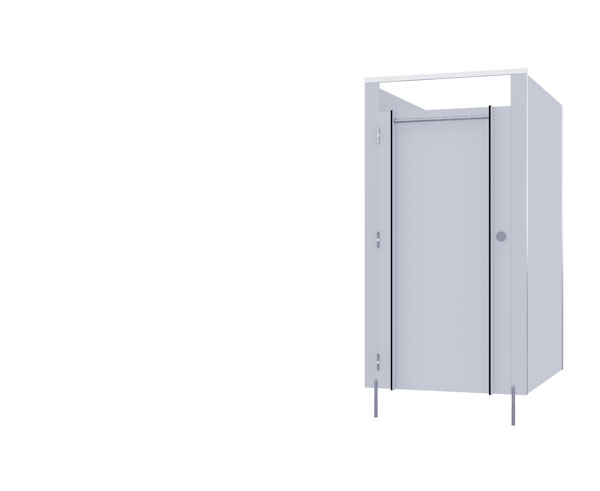

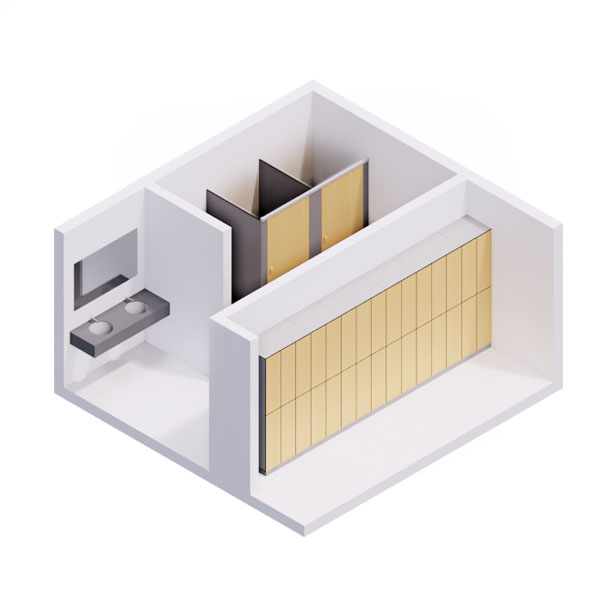

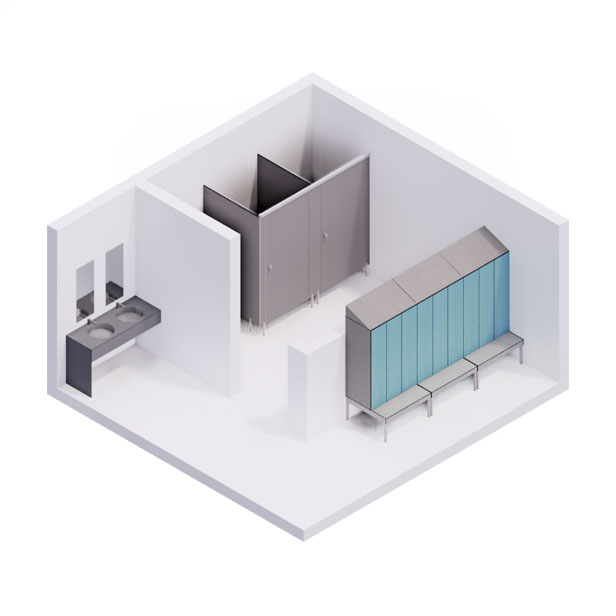

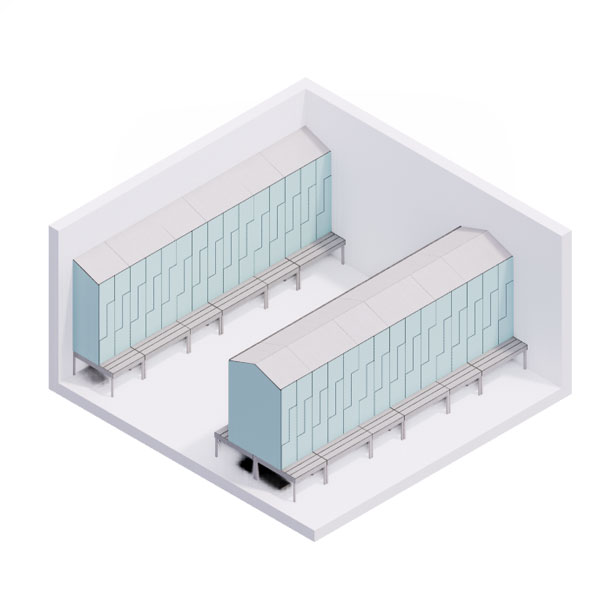

For sanitary building manufacturer ALSANIT, lightweight structures are mainly toilet cubicles, changing rooms and shower partitions. They are made of two materials with different properties: HPL board or MFC particleboard - what are the differences and which one is better? We answer in today's article.

Lightweight construction for public facilities

We can’t imagine places like movie theaters, swimming pools or manufacturing plants without sanitary facilities. Under this term are locker rooms, toilets and bathrooms, with lockers, showers and system cubicles. This complex infrastructure doesn’t come to our attention on a daily basis, unless… it’s missing (or when it’s extremely dirty, broken, etc.) in facilities such as:

- Schools, kindergartens, universities,

- museums, theaters cinemas,

- Hospitals, clinics, sanatoriums,

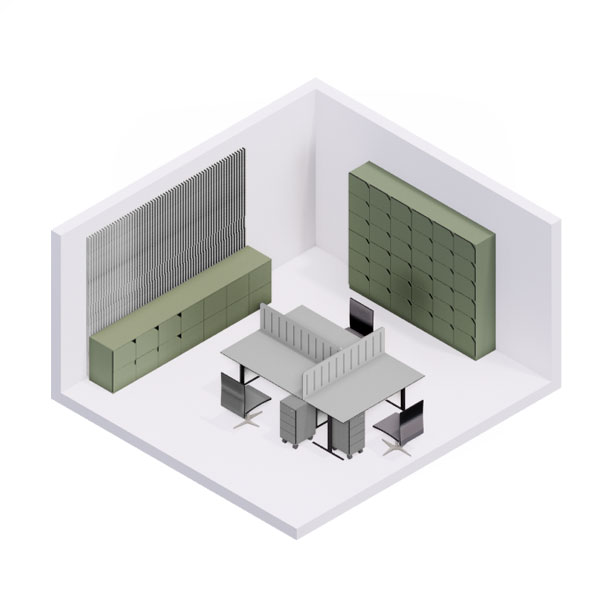

- workplaces, office buildings,

- Gyms, swimming pools, stadiums,

- shopping malls,

- luggage storage facilities.

These items do not close the list of locations where toilet cubicles, shower partitions or changing rooms are installed – there are many more. A suitably adapted sanitary room must be allocated for this type of light construction. Public bathrooms, changing rooms and toilets must meet the regulations specified in the relevant laws. Surely you have noticed that toilet cubicle systems in the above types of facilities have similar dimensions – this is due to the standardization of sanitary rooms, to which certain requirements are set. In order for system cabins and partitions to meet them, you need the right material for their construction. The most commonly used materials for toilet cubicles and other types of lightweight sanitary facilities are particleboard (MFC board) and HPL board.

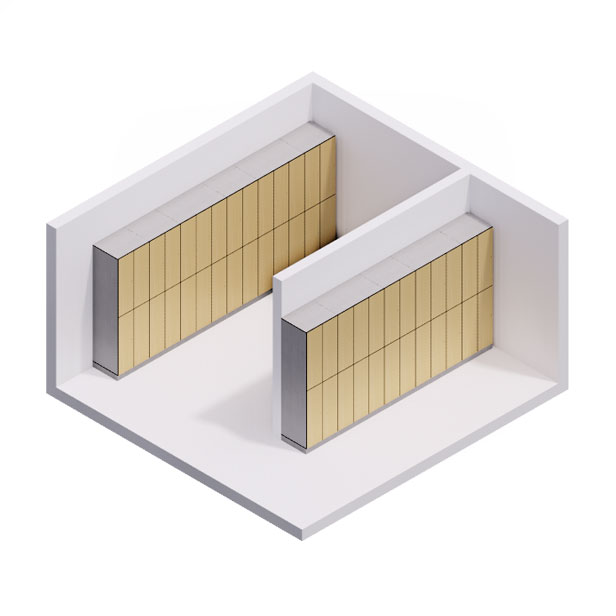

Construction of the HPL board

HPL stands for high pressure laminate. This term tells us a lot about the process of making HPL. High temperature and high pressure are required for production. Under these conditions, layers of core paper are hot-pressed (thermoset) to become a uniform panel for the construction of sanitary cabins. There is no risk of HPL delaminating, because during welding the material is impregnated and reinforced with melamine and phenolic resins, which are responsible for its consistency.

The board produced in this way can be processed in various ways – cut, drilled, milled with well-sharpened tools. Thus, HPL board is used to create advanced partition systems and sanitary cabins with practical accessories for any type of establishment.

HPL – the leader in sanitary construction

It is not without reason that we have presented a simplified process of HPL – it is thanks to high temperature and pressure, as well as impregnation in the form of resin, that the laminate gains its unique advantages. It can be confidently awarded the first place among the materials used for lightweight construction in the form of system cabins and sanitary partitions.

Thus, HPL board for the construction of system cabins has the following properties:

- It is resistant to mechanical damage – bending, impact or tearing. Durability is particularly important in the context of acts of vandalism, which unfortunately occur in public facilities.

- If we are talking about acts of vandalism, we should also mention acts of… “artistry”. Any damage in the form of inscriptions and graphics can be easily removed from the toilet cubicles, as the laminate enclosure is very easy to clean, as well as resistant to solvents, dyes and other chemicals.

- HPLtoilet cubicless and sanitary partitions are a worthwhile investment, as the material does not wear out. This is due to the aforementioned resistance to damage, as well as to abrasion. The gishet walls of system cabins remain in the same condition for years. In public facilities this is especially important, as there are always expenses more important than toilets and locker rooms….

- HPL board does not absorb water, which means it is resistant to moisture. There is no question of bulging, paint coming off or mold due to high humidity levels in the room.

- The surface of the laminate is free from fungi and bacteria. The high density of the material and the poreless structure inhibit the growth of microorganisms. Combined with moisture resistance, we get an ideal set of features for various types of swimming pools (sports swimming pools, aquaparks, hotels, spas, etc.) and other facilities exposed to high levels of humidity.

Applications of MFC particleboard – construction of sanitary cubicles

An alternative to laminate for dry rooms is particleboard, also known as MFC. It, too, uses resin for its construction, but in this case the properties obtained are not as impressive as in HPL. Nevertheless, particleboard is a very popular material for lightweight construction because of its price. It is definitely cheaper than its predecessor, and at the same time durable.

- Particleboard is resistant to scratches and abrasion, so its appearance remains unchanged for a long time.

- Despite their advantages, particleboard structures are less expensive than their HPL counterparts.

- MFC system cabins are easy to keep clean and do not require the purchase of special detergents.

- Easy machining allows toilet cubicles and other sanitary structures to be made to size, making the most of the available space.

- Particle boards take on one of the decors and colors. Thanks to the variety of shades and patterns, system cabins and sanitary partitions gain an aesthetic, original look that enlivens often neglected rooms.

Which material is better for lightweight construction?

In summary, HPL boards are used wherever the construction will be exposed to water or moisture. So it is mandatory to use them for the construction of system cabins and shower partitions. In addition, choose laminate for all types of construction (not only showers, but also changing rooms or toilet cubicles), if the conditions of the facility require it.

If you do not anticipate moisture in the sanitary room, consider lightweight particleboard construction, which is less expensive. However, the highest strength and longest life of sanitary cabins is always provided by HPL boards.

Ask – we will advise!FAQ:

1. How is HPL better than particle board?

HPL laminate, which is used to make sanitary cabins, is resistant not only to mechanical damage, but also to moisture and water. In addition, its surface inhibits the growth of microorganisms.

2 What are the advantages of particle board?

MFC board is less expensive than HPL board. It comes in many decors and color variants, which allow you to design original sanitary facilities, such as system cabins.

3. Which plate to choose for lightweight construction?

If there may be moisture in the room, choose HPL. Otherwise, consider both options.